The Bunnings Workshop community can help with your home improvement projects.

- Bunnings Workshop

- >

- How To

- >

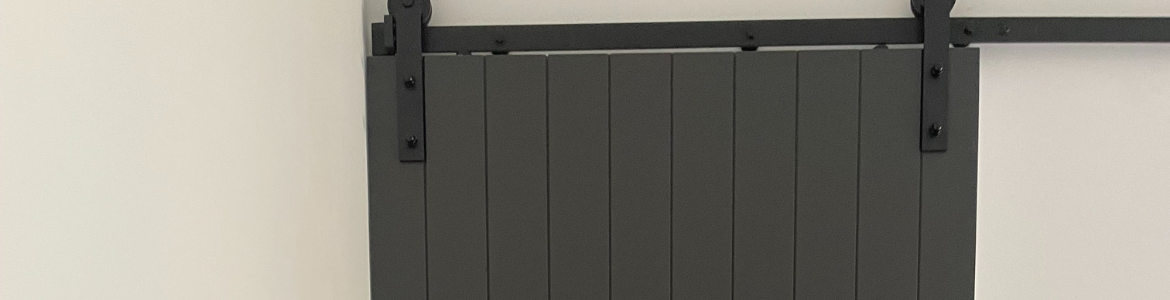

- How to build a barn door with VJ panels

How to build a barn door with VJ panels

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Difficulty: Intermediate

Barn doors are a great way to create privacy in your home. They can also be used to add style and character.

Here is a step-by-step guide to creating a custom barn door. You can use our measurements or adjust them to suit your own set-up.

As this project involves power tools, please follow all safety guidelines provided by manufacturers and use the recommended protective gear.

Let us know if you have any questions. We’d be happy to assist.

Steps

Step 1

Measure and mark your VJ panel sheets.

Determine the width and height of your wall opening by using a tape measure. Then add 50mm to both the height and the width to ensure the door is slightly taller and wider than your opening.

Mark out your custom measurements on your VJ panels with a tape measure. My door measured 908 x 2400mm.

Step 2

Cut the VJ panel sheets.

Cut out your VJ panel sheets based on your marked measurements with a circular saw. Don’t forget to wear personal protective equipment (PPE) while cutting, including safety glasses.

For straight cuts, you can place one of the sheets on top of the other as a guide. Use clamps to secure them.

Step 3

Mark and cut a border frame for the VJ panels.

Place one of the cut VJ panel sheets downwards on a flat surface so that the back is facing upwards.

Now take two lengths of 2400mm 42 x 19mm dressed Pine and cut them to match the length of your vertical sides. My sides measured 2400mm each so I didn't have to cut the lengths.

Place those on the sides of your panel and measure the distance between them. Cut four lengths of the 42 x 19mm dressed Pine to suit. I cut four lengths measuring 900mm.

Place two lengths horizontally on the top and bottom sections of the VJ panel sheet. Then place the remaining two lengths in the middle. Make sure they are evenly spaced. In my case they were 900mm apart.

All the dressed Pine lengths should fit perfectly when placed together to form a frame split into three sections.

Step 4

Secure the dressed Pine frame to the VJ panel sheets.

Apply pea-sized amounts of construction adhesive on the outer side of the dressed Pine frame, spaced about 5cm apart. Then place a second VJ panel sheet on top of the frame and glue the sheet and frame together. Make sure the grooves of the sheet are facing outwards away from the frame. Don't use too much adhesive for this step as it can leak.

Once dry, flip the VJ panel sheet and glued frame so that the frame is facing upwards. Apply adhesive on the outer side of the dressed Pine lengths again and then place the first VJ panel sheet on top of the frame, gluing them together. As with the previous sheet, the grooves should be facing outwards.

Your frame should now be in the middle of two VJ panel sheets, forming a door.

Step 5

Nail your VJ panels to the frame.

To secure the door further, nail the dressed Pine frame to the VJ panel sheets. Draw a small cross or arrow to mark your nail points along the areas where the sheets and frame intersect.

Now use a nail gun to nail six nails on the sheet along both vertical sides of the frame lengths. Then nail three to four nails along the top and middle of the sheets. Make sure to press down on the sheet while nailing to avoid any gaps between the sheet and the frame.

Step 6

Fill any holes on your door.

Use a gap filler to fill in any small holes created by the nails. Apply a small amount of gap filler in any holes using a scraper. Make sure the hole is completely filled.

Let the filler dry for 30 minutes.

Once dried, sand it by hand using a 120-grit sanding paper for a smooth finish.

Step 7

Make a hole for the flush pull handle.

Measure and mark out your preferred spot for the door handle. I placed my handle 100 cm away from the floor and 39cm away from the right edge of the panel.

Once you've marked the handle spot, drill a hole measuring 51mm in diameter using a drill driver with a holesaw attachment.

Wipe off any sawdust using a damp cloth.

Step 8

Once your door is clean and dry, it’s time to start painting. I chose two different colours for both sides of the door. I went with a white colour to match my walls for one side and chose a darker colour for the other to create more depth and interest.

Use a 100mm x 4mm roller to paint the first side of your door. You can also use a brush when painting over the grooves. Apply two coats for a better finish. Wait approximately two hours for the first coat to dry before applying the second.

Leave the painted side of the door to dry for 24 hours. Then flip the door and paint the second side, repeating the process.

Step 9

Install the flush pull handle.

Once the paint has fully dried, apply adhesive on the inner side of both pieces of the flush pull handle and glue it into the door from both sides. There will be a small hole on one side of the handle. Make sure to position the handle so that the hole is on the side where the dressed Pine frame is.

Now use a screwdriver to screw in the small screw provided into the frame.

Your VJ panel barn door is now ready for installation and use.

Materials

-

65mm stainless steel round flush pull handle two pack

-

Two sheets of Easycraft 2400 x 1200mm 9mm Lining Panel White MRMDF Primed VJ 100mm

- 32mm nails

- Gap filler

- Construction adhesive

-

Two lengths of 42 x 19mm 2.4m DAR Pine Premium

-

Two lengths of 42 x 19mm 1.8m DAR Pine Premium

- Paint

-

120-grit sanding paper.

Tools

- Pencil

- Tape measure

- Drill driver

- Five piece hole saw set

- Clamps

- Nail gun

- Paint roller

- Paintbrush with tray

- Damp cloth

- Safety glasses

- Screwdriver.

Images

You must be a registered Workshop community member to comment. Please join Workshop or sign in to join in the discussion.

Why join the Bunnings Workshop community?

Workshop is a friendly place to learn, get ideas and find inspiration for your home improvement projects

You might also like

We would love to help with your project.

Join the Bunnings Workshop community today to ask questions and get advice.